Synthetic Enamel Marine

Synthetic Enamel Marine Specification

- Shape

- N/A (applies as paint film)

- Size

- 1 L, 4 L, 20 L packs

- Adhesive Side

- Single Side (applied to surface)

- Max Temperature(Degree Celcius)

- 100C

- Coverage Area

- 130-150 sq.ft./L/coat

- Application Method

- Brush, Spray, or Roller

- Particle Size

- Fine (homogeneous suspension)

- Feature

- High Gloss, Corrosion Resistance, Durable Finish

- Adhesive Strength

- Strong adhesion to primed metal surfaces

- Thickness

- Recommended 25-30 micron per coat (dry)

- Material

- Synthetic Resin Enamel

- Usage

- Industrial, Marine Applications

- Form

- Liquid

- Color

- Blue (standard), Customized colors available

- Purity(%)

- 99%

- Application

- Surface Coating, Protection of Marine Vessels and Equipment

- VOC Content

- Complies with IS standards

- Base Type

- Oil-based

- Finish Type

- Glossy

- Storage Condition

- Store in cool, dry and well-ventilated area

- Drying Time Hard Dry

- 8-12 hours

- Recoating Interval

- 8 hours minimum

- Shelf Life

- 12 months in sealed container

- Substrate Compatibility

- Metal, Wood, Primed Surfaces

- Drying Time Surface Dry

- 1-2 hours

- Resistance

- Water, Alkali, Mild Chemicals

- Packing Type

- Tin Container

- Weather Resistance

- Excellent (Marine grade)

About Synthetic Enamel Marine

Directions & Industrial Usage for Synthetic Enamel Marine

Synthetic Enamel Marine is used for coating metal, wood, and primed surfaces, providing durable, glossy protection to marine vessels and equipment. For best results, apply using a brush, spray, or roller on clean, dry surfaces at a recommended thickness of 25-30 microns per coat. Plant application is straightforward: ensure surfaces are properly primed and maintained. This enamel excels in industrial and marine settings, delivering a superior finish and excellent weather resistance for long-term usage.

Packing, Certifications & Delivery for Synthetic Enamel Marine

Packing & Dispatch of Synthetic Enamel Marine is handled in sturdy tin containers, with sizes suitable for diverse application needs. FOB Port options are available across major Indian ports for seamless expenditure and delivery. The product is certified to comply with IS standards, ensuring reliability and safety. Samples are available upon request, enabling informed purchases for dealers, exporters, and importers. Efficient distribution guarantees prompt delivery, minimizing downtime for supplier and end-user alike.

FAQ's of Synthetic Enamel Marine:

Q: How should Synthetic Enamel Marine be applied for optimal results?

A: Synthetic Enamel Marine should be applied with a brush, spray, or roller, ensuring the surface is clean and primed. Maintain a coat thickness of 25-30 microns for superior adhesion and finish.Q: What types of surfaces can Synthetic Enamel Marine be used on?

A: This superior enamel is compatible with metal, wood, and primed surfaces, making it ideal for both marine vessels and industrial equipment.Q: When is it safe to recoat surfaces after applying Synthetic Enamel Marine?

A: A minimum recoating interval of 8 hours is recommended. Surface drying occurs within 1-2 hours, while hard drying completes between 8-12 hours.Q: Where can Synthetic Enamel Marine be purchased and delivered?

A: Synthetic Enamel Marine is available through dealers, distributors, exporters, importers, manufacturers, and retailers across India, with delivery options from major FOB ports for efficient supply chain management.Q: What are the primary benefits of using Synthetic Enamel Marine?

A: Benefits include high gloss finish, outstanding weather and corrosion resistance, durable protection, strong adhesion, and compliance with IS VOC standards.Q: Is there a process for obtaining product samples before a larger purchase?

A: Yes, samples of Synthetic Enamel Marine are available upon request, allowing you to evaluate quality and suitability prior to full expenditure and order placement.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Protective Coating Primer Category

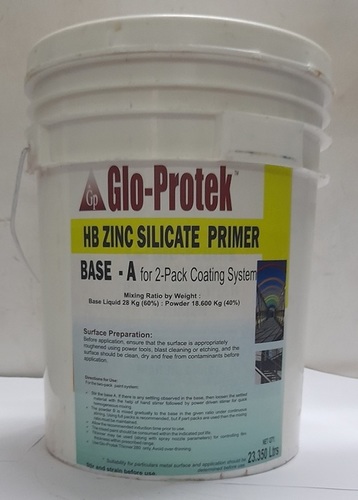

GLO-PROTEK HB ZINC SILICATE PRIMER

Feature : Excellent resistance to solvents and abrasion, superior corrosion protection

Application : Corrosion protection of steel surfaces, marine and structural steelwork

Form : Other, Liquid

Material : Other, High Build Zinc Silicate

Epoxy Zinc Rich Primer

Price 310 INR / Liter

Minimum Order Quantity : 5 Liters

Feature : Corrosion Resistant

Application : Industrial

Form : Liquid, Other

Material : Other, Epoxy Zinc

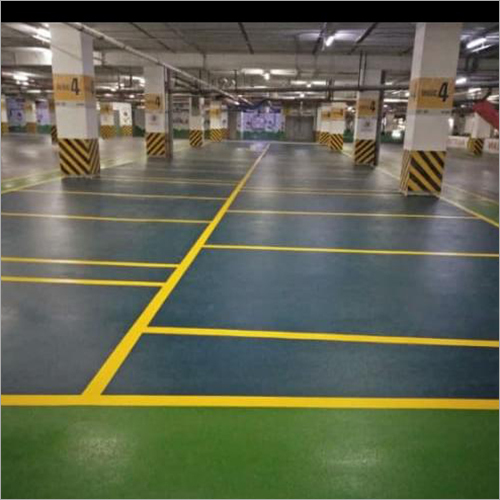

C-Epoxy Car Parking Floor

Feature : Durable and High Load Bearing

Application : Car Parking Floor

Form : Liquid (Epoxy Resin), Other

Material : Epoxy

Lpoxy High Solid Surface Tolerant Primer

Price 350 INR / Liter

Minimum Order Quantity : 5 Liters

Feature : ANTICORROSIVE PRIMER

Application : ANTICORROSIVE PRIMER